Plywood

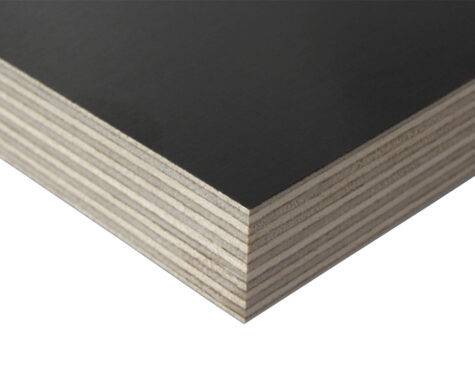

Plywood is a material manufactured from thin layers or “plies” of wood veneer that are glued together with adjacent layers having their wood grain rotated up to 90 degrees to one another.

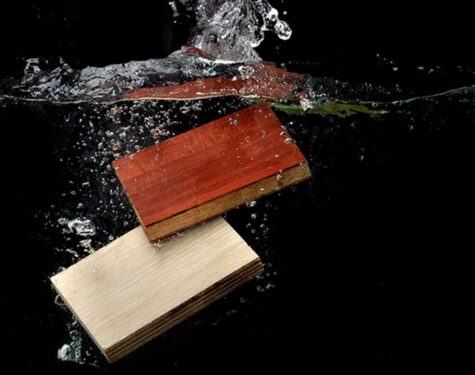

All plywood bind resin and wood fiber sheets (cellulose cells are long, strong and thin) to form a composite material. This alternation of the grain is called cross-graining and has several important benefits: it reduces the tendency of wood to split when nailed at the edges; it reduces expansion and shrinkage, providing improved dimensional stability; and it makes the strength of the panel consistent across all directions. There is usually an odd number of plies, so that the sheet is balanced—this reduces warping. Because plywood is bonded with grains running against one another and with an odd number of composite parts, it has high stiffness perpendicular to the grain direction of the surface ply.

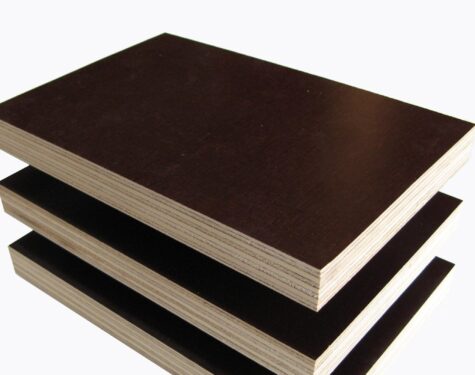

Plywood is used in many applications that need high-quality, high-strength sheet material. Quality in this context means resistance to cracking, breaking, shrinkage, twisting and warping.

A typical plywood panel has face veneers of a higher grade than the core veneers.

The principal function of the core layers is to increase the separation between the outer layers where the bending stresses are highest, thus increasing the panel’s resistance to bending. As a result, thicker panels can span greater distances under the same loads. In bending, the maximum stress occurs in the outermost layers, one in tension, the other in compression. Bending stress decreases from the maximum at the face layers to nearly zero at the central layer. Shear stress, by contrast, is higher in the center of the panel, and at the outer fibres.