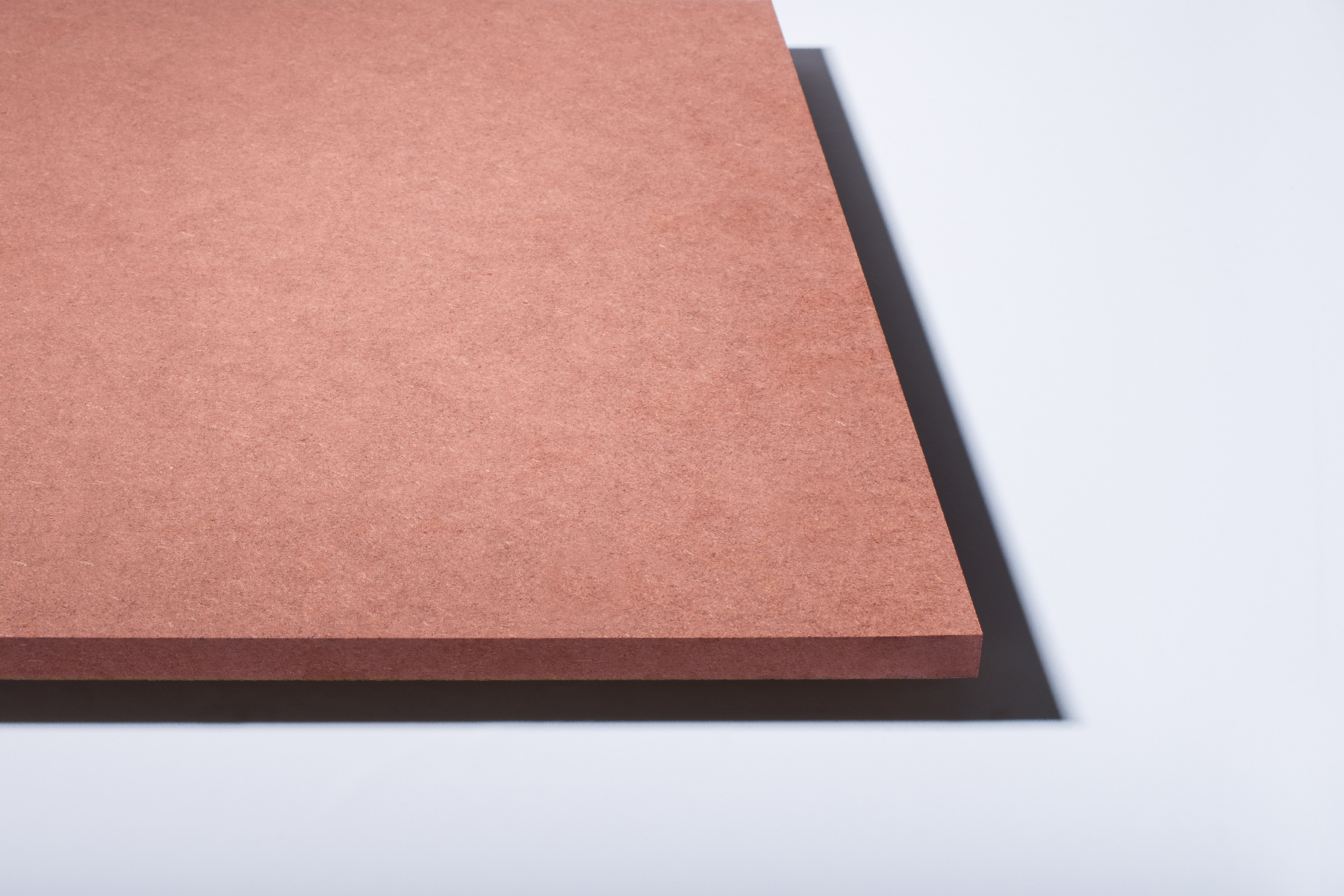

Medium Density Fiberboards (MDF)

Medium-density fibreboard (MDF) is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibres, often in a defibrator, combining it with wax and a resin binder, and forming it into panels by applying high temperature and pressure.

MDF is generally more dense than plywood. It is made up of separated fibres, but can be used as a building material similar in application to plywood. It is stronger, and more dense, than particle board.

MDF may be glued, doweled or laminated. Typical fasteners are T-nuts and pan-head machine screws. Smooth-shank nails do not hold well, and neither do fine-pitch screws, especially in the edge. Special screws are available with a coarse thread pitch, but sheet-metal screws also work well. MDF isn’t susceptible to splitting when screws are installed in the face of the material but, due to the alignment of the wood fibres, may split when screws are installed in the edge of the board without pilot holes.

- Consistent in strength and size

- Shapes well

- Stable dimensions (less expansion and contraction than natural wood)

- Takes paint well

- Takes woodglue well

- High screw pull-out strength in the face grain of the material

It is available in raw form, or with a finely sanded surface, or with a decorative overlay. MDF is used for furniture such as cabinets, because of its strong surface.